The chemical and materials industry is one of the fastest growing segments in manufacturing industry, transforming raw inputs into more than 70,000 products for intermediate or final consumption. The majority of the industry's output comes from polymers and plastics. These materials are vital for other industries such as manufacturing, construction and agriculture. Advancements in technology allow the chemical industry to remain innovative and cater for the specific demands of its consumers.

The chemical and materials industry serves a broad range of adjacent industries, and features at the beginning of the value chains of numerous sectors, such as agriculture, food and beverages, consumer goods, construction, the plastics industry, automobile industry, glass industry and pharmaceuticals.

The advent of novel products and applications, rising environmental awareness, and changing consumer preferences are positively impacting the growth of chemicals and materials industry.

The chemicals market covers chemicals produced via the transformation of organic and inorganic raw materials by a chemical process and the formulation of products.

Chemicals broadly include bulk petrochemicals, lubricants and intermediates, minerals, polymers, and other derivatives, resins, polymers and speciality chemicals, industrial gases, fertilisers, paints and coatings, adhesives and sealants, plastics and rubber products. A number of consumer goods are also included, such as synthetic fibers, pharmaceuticals, hygiene and personal care products, cosmetic additives, fragrances, and toiletries, cleaning materials, soap, detergents, bleaches.

Bulk inorganic chemicals, or commodity chemicals, (such as nitric acid, hydrochloric acid, sulphuric acid, phosphoric acid, ammonia, sulphur, limestone, halogens, soda ash, serve as intermediates for a range of specialty chemicals - like adhesives, sealants, anti-oxidants, additives, coatings and corrosion inhibitors with applications in construction, marine, aerospace and defense, automotive and other industrial applications.

The Paints & Coatings sector is one of the most regulated sector that has undergone several technological developments. focusing on developments in both organic and inorganic paints and coatings and nanocoatings.

The growth of ancillary industries in emerging economies, as well as the new trend in bio-based and renewable chemicals, have been key to the growth of the chemical and materials industry over the recent past.

Environmental protection, social responsibility, and economic growth are the prerequisites that the industry needs to satisfy to sustain growth, against a background of concerns regarding emissions of hazardous materials, and stringent regulations.

Demand for bio-based products, organic fertilizers, bio plastics, and renewable chemicals, as well as government regulations endorsing the use of eco-friendly products are driving growth, as green chemicals , such as green dyes, bio succinic acids, and green plastics are increasingly adopted in commercial, residential and infrastructural projects.

A large part of the high investment required in the chemical industry is for equipment, machines, and tools that are used to process chemicals. The capital intensity of bulk chemicals (equipment for material handling, mixing, polymer processing, heat transfer, reactors, evaporators, separators, dryers, pollution control) act as an entry barrier for new entrants in this market, and have relatively little scope for product differentiation and product development. The industry also needs technologists and designers to respond to the worldwide demand for more versatile, lightweight, energy-saving products and applications.

The global chemical industry will retain a focus on production efficiencies, managing cash flow, securing raw materials, abide to regulations and carbon emissions quotas pushing companies towards greener products and limit the use of petrochemical-based intermediates.

Companies like Dow Chemical, DuPont and LyondellBasell from the U.S., BASF and Bayer from Germany, and Saudi-Arabian Saudi Basic Industries are leading the chemicals sector.

Adhesives & Sealants

The adhesives and sealants market enjoys industry-wide usage across every manufacturing industry – FMCG, textiles, flexible packaging, construction, automotive, aviation, and healthcare sectors.

Adhesives and sealants have discovered widespread popularity in. As per recent studies, growth in emerging nations is likely to grow at a fast pace driven by rapid industrialization.

Plastics & Rubber

With both products being derived mainly from petrochemicals, the synthetic rubber industry and the plastics industry form a coherent subsector.

The plastics industry is an important segment of the chemical industry, largely dominated by the top global players of the branch, like LyondellBasell, Dow Chemical, DuPont, BASF, and Bayer.

The total global production of plastics amounts to approximately 300 million metric tons annually. The leading producer of plastics is China, manufacturing around a quarter of the world’s production.

The rubber industry is also a subdivision of the chemical industry. Around 60 percent of the total global rubber production today is produced synthetically.

Industrial gases

Industrial gases (nitrogen, oxygen, acetylene, carbon dioxide, hydrogen, helium, argon) are used in a wide range of industries, which include manufacturing, oil and gas, chemicals, power, mining, steelmaking, food, water, fertilizers, electronics, aerospace, medicine, pharmaceuticals, biotechnology.

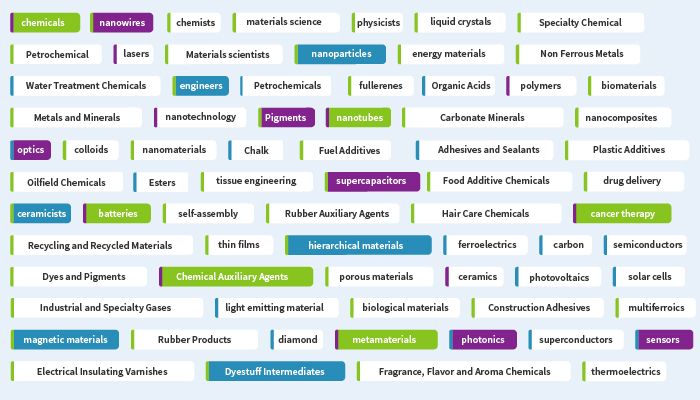

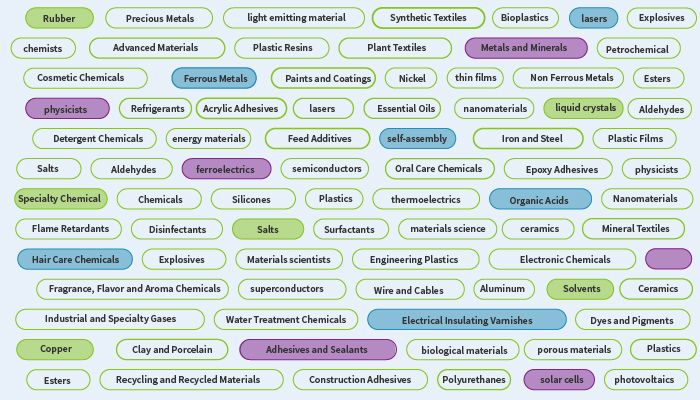

Research focus areas are in the competitive landscape, key players, present and future market scenarios, growth inducing trends and challenges in petrochemicals, specialty chemicals, including petrochemicals, specialty chemicals, agrochemicals, chemical fertilizers, pesticides, fungicides, herbicides, insecticides, renewable chemicals, traditional and biodegradable plastics, resins, paints and coatings, water treatment chemicals.

Chemicals

Agrochemicals, petrochemicals, bio-chemicals and also synthetically derived chemicals. Coatings, specialty chemicals, fine chemicals, commodity chemicals, catalysts, resins, gases, pesticides and others.

Plastics

Plastics additives, thin films and coatings. Polyethylene, polyurethane, polystyrene, polypropylene, packaging, rigid plastics, thermoplastics and others.

Advanced Materials

Metals, alloys and non-metal products, composite materials, liquid crystals, ion exchange, engineering plastics, polymers, cellulose, ceramics, glass, construction materials, plasma and others.

Separation Technologies for membranes, recycling, water and waste treatment, -reverse osmosis, ultra-filtration, microfiltration, desalination-, as well as physical separation technologies -activate carbon, carbon block, dust filters, and ion exchange materials.

Nanotechnology

This area covers the latest movements and opportunities for nanotechnology, including nanoparticles, carbon nanotubes, nanocomposites, nanoclays, nanofibers, quantum dots, nanoceramic powders, graphene, Mxene.

Chemicals and Advanced Materials

Chemicals and Advanced Materials