Eugene M. Terentjev, Professor of Polymer Physics from the University of Cambridge, enlightens us on Smart Plastics, specifically on how liquid crystalline elastomers bring automation into materials

While we are used to automation, machine learning and AI in the technology sector – known as the Fourth Industrial Revolution – polymer researchers at Cambridge have now developed a new class of materials with physical intelligence. These are plastics that feel and respond to their environment, making decisions, analysing and diagnosing problems without human intervention. Liquid crystalline elastomers are truly the material of the future.

The focus of the Horizon 2020 project APRA (Advanced Grant “Active Polymers for Renewable Functional Actuators”) is achieving autonomy through intrinsic material function rather than relying on embedded electric or mechanical solutions. We have developed these multifunctional polymer materials, and ensured that they remain sustainable by keeping them recyclable and reprocessable despite relying on their crosslinked nature – all made possible by the novel chemistry of dynamic bond exchange.

What are Liquid Crystalline Elastomers?

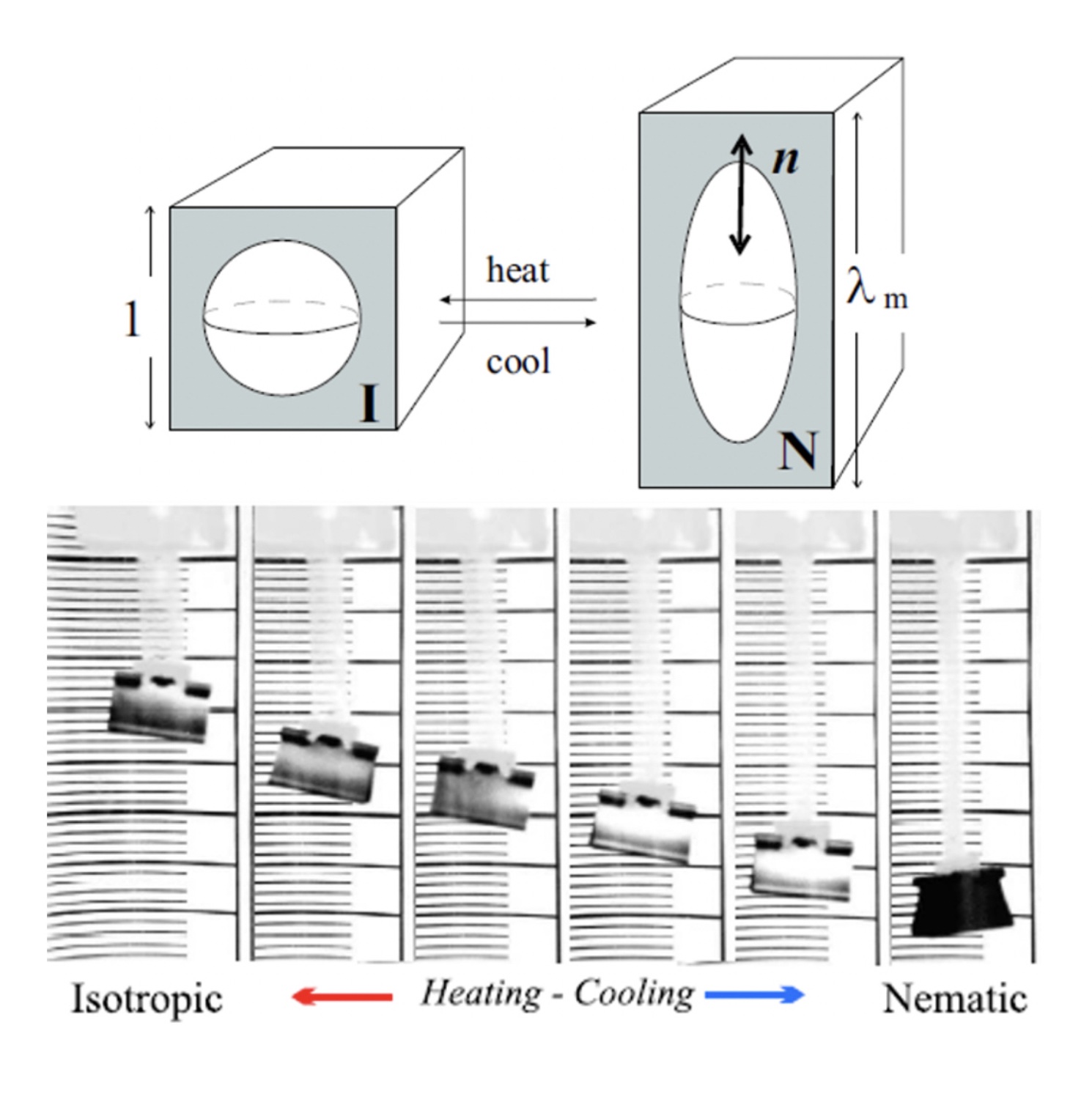

Liquid crystal elastomers (LCEs) are a radically new polymer system, akin to rubber, but with remarkable and unexpected properties that arise from its intricate molecular structure. The polymer had rigid rod-like units separated by flexible chains. This structure allows for local liquid-crystalline order with the anisotropy axis, where the rods align. These rods can then rotate separately and independently of the overall rubber-elastic matrix.

The invention and the early studies of LCEs made almost 30 years ago, have laid out the fundamentals of understanding these materials. Our research group was at the foundation of these studies. The new generation of robust main-chain LCEs developed under the APRA programme is based on dynamic networks (sometimes called ‘vitrimers’) that allow re- moulding the crosslinked thermosets and re-programming their local orientational order. This also makes the material one of the first totally recyclable thermoset plastics.

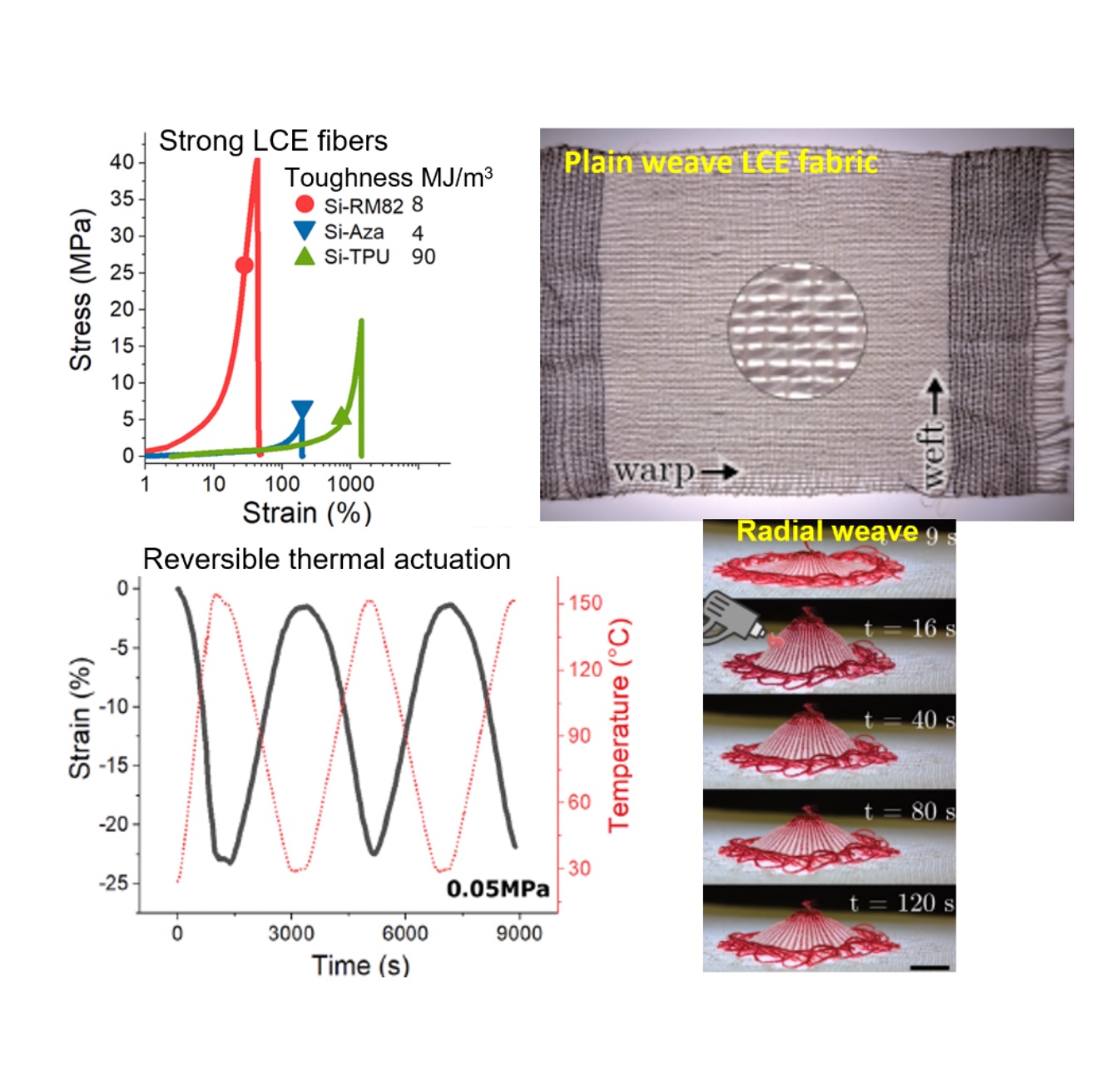

One unique LCE property is called ‘soft elasticity’, which combines the dissipation properties of a liquid with the mechanical strength of a thermoset to produce levels of vibration damping far above market-leading technologies based on polyurethane or silicone. This plays with the alignment of the rod-like molecular segments as fluctuation in their alignment converts energy to heat, much like friction. The sound or physical vibration will deliver the energy, but none will pass through the material.

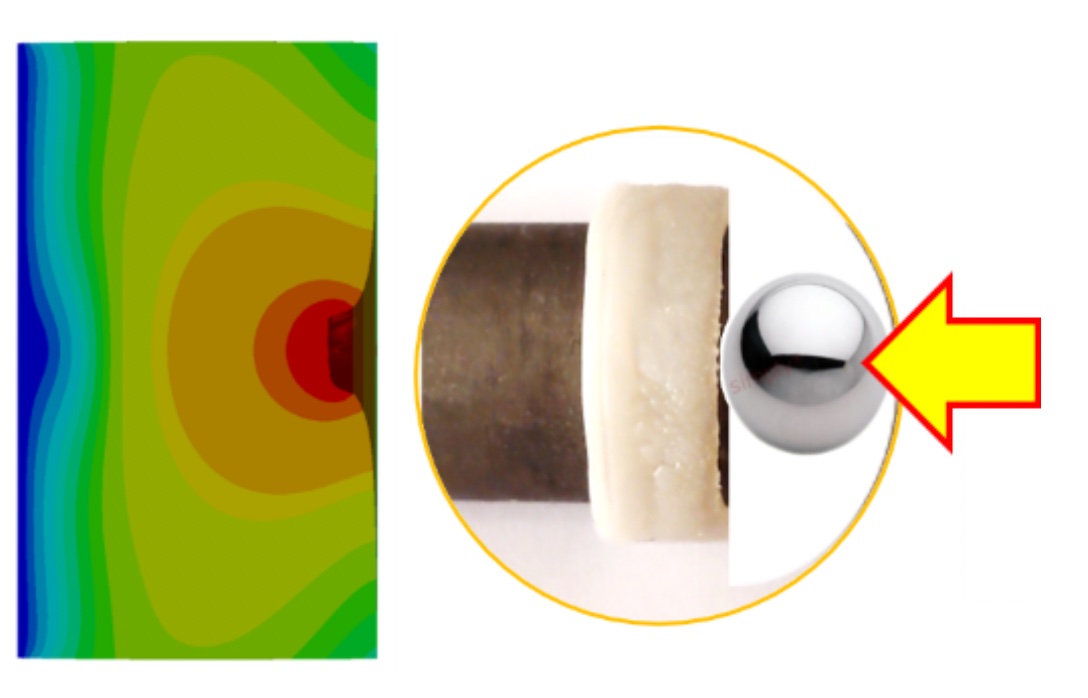

Adhesion energy is very closely related to mechanical damping, so LCE can also exhibit a strong pressure-sensitive adhesion (PSA). It will feel sticky to touch and bond to most surfaces. However, simply heating the LCE will turn it into a smooth isotropic elastomer with little or no surface energy giving a reversible adhesive property to LCE.

The other fascinating effect, which promises ground-breaking applications and devices, is that LCEs reversibly contract and expand on heating and cooling. If the material is programmed to a given shape when aligned, then this will become its natural shape. However, heating the material will cause up to 100-200% contraction, which is fully reversible (the LCE extending back into its natural shape when cooled). This mechanical actuation allows us to design actuators, artificial muscles, or an LCE engine working on a difference in temperature between two containers.

Despite their long history in academic research, LCEs are only beginning to penetrate

industrial applications and design, and our team have been at the very beginning of this development. We work together with the start-up Cambridge Smart Plastics, developing marketable LCE applications in vibration isolation, reversible adhesion, microfluidics, and even working on the LCE engine converting waste heat into useful work.

Applications

Vibration and acoustic damping – the simplest use for LCE would be to leverage its internal damping to create sound isolation pads, or dampen vibration from the road to improve the accuracy of LIDARs and/or passenger comfort.

PSA pads – utilising thin layers of LCE will enable fully reversible adhesive tapes that will eliminate the “single-use” nature of today’s adhesives. Most technology, especially many automotive systems, are totally held together by adhesive tapes that must be disposed of and replaced during repairs. LCE adhesive tapes would simply release on heating and then be free to be reused in the same product or elsewhere.

“Smart” structures – leveraging the artificial muscle, simple demonstrators have already been produced for heliotracking solar panels. Using the light to trigger the actuation, a platform can be built that will always lean towards the light increasing the contact angle and power generation of the panel.

Heat to energy conversion – storing waste heat in the LCE will allow energy to be held in the material. This can be through a simple motor design or by lifting weights or pumping water using the LCE’s actuation.

Bringing the state-of-the-art in polymer science to industry

Cambridge Smart Plastics is a start-up that aims to revolutionise commodity plastics, accelerate innovation and technology translation, and foster our next generation of innovators. Embedded in the University of Cambridge, they are building industrial collaborations and scaling up the demonstrators and technologies developed here to introduce these materials into the market. These LCE materials really have a chance to make a difference with the reversible PSA characteristics making sustainable reusable adhesives tapes viable, or recyclable elastomers for damping applications like isolating LIDARs for increased accuracy and safety of vehicles.

If you would like to learn more or join Cambridge Smart Plastics on this journey, then reach out today. The team is always excited to hear ideas and co-develop applications for this exciting new material.

The University of Cambridge, through its ERC- funded APRA project, and the technology spinoff Cambridge Smart Plastics are developing a new concept using liquid crystalline elastomers which are reversibly adhesive, as simple as a hand that grips and let’s go on demand.

We have made a naturally sticky rubber that a little heat will alter and allow easy detaching. On cooling, these surfaces immediately get sticky again and are ready to get to work and have a second life. The world’s first in terms of a truly reusable adhesive.

Pressure-sensitive adhesion and the future of reusable tapes

Pressure-sensitive adhesion (distinct from the adhesion by gluing) is a large and expanding field of science and technology, relying on tacky and sticky surfaces. All adhesive tapes are single-use and disposable by their nature. Since over 45 billion square metres of pressure-sensitive adhesion (PSA) tapes are produced annually, the environmental impact should not be underestimated.

Even structural bonding tapes that claim to last for a product lifetime end up replaced by new when repairs or adjustments are made. There is also no realistic route to recycling such tapes given the chemicals at play, the compounded plastics or fabrics carrying them, the spoiling of surfaces and/or polymerisation of glues.

Looking at the state-of-the-art in adhesive tapes, there is no truly reusable tapes. The nearest state-of-the-art exists rely on simple concepts like “hook-and-loops” on each side to create a Velcro, or alternatively a sticky elastomer is stretched to detach, but at the cost of destroying the tape.

On the premium and performance end of the market, the best technologies rely on weakly crosslinked polymers. These leave no residue and are reusable until they spoil (surfaces contaminated), but delaminating them is difficult as the full strength of the adhesive must be overcome and this often leads to tearing or damage to the tape itself.

Current and future chemicals regulation affect adhesive tapes

Incoming EU bans for ADCA, DEHP, toluene, and formaldehyde (essential blowing agents for rubbers, plasticisers, and solvents), or the increasing focus of the anti-plastics lobby on how tapes have “dodged” the requirements for recycling (both incorporating and their own end-of-life).

Liquid crystalline elastomers (LCE) represent a highly unusual and exciting ‘new state of matter’, first introduced in the early 1990s by the work of Finkelmann, Warner and Terentjev. By utilising the known properties of liquid crystals in a rubbery polymer network, some remarkable functionalities were obtained. The main buzz, and the focus of researchers over the last few decades has been exploring the thermal and photo- actuation properties of LCE (including our own ERC APRA project).

In the liquid crystalline temperature range, the mesogens that make up the core of this material, align and stretch the polymer chains into an elongated conformation. By heating the sample, this orientation is lost, and the polymer backbone can relax into a more favoured random-coil conformation. This leads to a macroscopic, reversible deformation called the large-stroke actuation, where all the attention was until now.

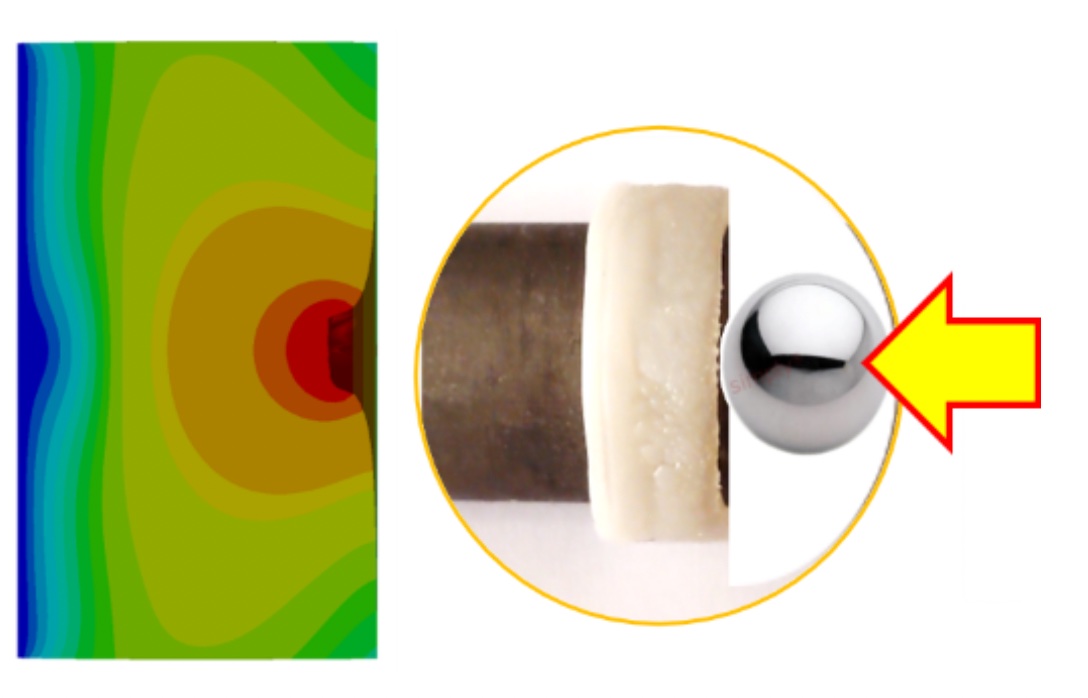

Fundamentally changing surface interaction

In our recent studies, we found a direct link between the internal viscoelastic loss in the material (tand) and the strength of pressure-sensitive adhesion. Since the anomalous damping (high tand) only exists above the glass transition of LCE, and below its nematic-isotropic transition temperature TNI, the high PSA is only found in this temperature range – by heating above TNI, the surface becomes non-adhesive – but on cooling back below TNI, into the ambient range, the strong surface adhesion is recovered.

Such reversible PSA provides a specific and targeted application to realise immediate value from the LCE research. Our solution to reversible PSA is radically different as the introduction of heat or similar stimuli will fundamentally change the surface interaction and make delaminating easy, so that the surface releases much of what spoils regular tapes. The LCE adhesive tape will also recover its natural shape immediately as in isotropic phase the shape memory element of the more strongly crosslinked network will kick in. Spoiling risk is also reduced as the surface is no longer sticky when delaminating and can be quickly protected or re-applied to another surface. As such, it is a paradigm shift.

We envisage product repairs conducted quickly and easily with the existing tape reused or wearable tech (e.g. medical sensors or bandages) that can be removed with warm water or washing, ready to be reapplied once cooled and dried. The reusability of a PSA will increase the useful life of products and will challenge the “replace with new” culture in manufacturing and repairs. We also forgo the need for solvents and cleaning to remove tapes and residue. The performance of LCE, as a superior bonding and damping material, will also be powerful in terms of light-weighting, given it has higher performance per volume and leads to thinner tapes, or offshoot products like mounts, washers, bushings, etc. in sectors like automotive.

Addressing UK and EU policies on plastic waste

We see this product being used not just for adhesion but as a vibration-damping layer in sensitive systems like LIDAR to increase their accuracy or in power tools to reduce their vibration effect on the holder. There are also direct environmental benefits to the end-of-life with this technology too. Our 3d-generation exchangeable xLCE systems are crosslinked by dynamic bond-exchange chemistry, which makes it recyclable and re-processable thermoset plastic (vitrimer), unlike any standard elastomeric material. That means even when the product is thrown away, there is a possibility to recover and reuse it. The covalent crosslinks are dynamic and the polymer will flow under heat & stress, and allow itself to be remoulded.

This project addresses UK and EU-wide policies on plastic waste and recycling by introducing reusability, and fits neatly to the EU and UK priorities, e.g. the “Clean Growth” Grand Challenge of the Department for BEIS and EU Green Deal. Specifically, advanced materials technology, where opportunity lies in developing small businesses like Cambridge Smart Plastics, “closely coupled to local universities”. Through our collaboration and know-how transfers, we invest into human capital and skills not just in academic journals, but direct to industry across EU through our industrial partners.

The ‘smart materials’ is a cliché used broadly in many areas of modern technology, in each case meaning different things. Liquid Crystal Elastomers (LCE) have been invented over 30 years ago, and ever since been considered a highly promising material system for soft actuators and artificial muscles. The fully- reversible mechanical response induced by heat, or by light, is based on intrinsic material properties of Liquid Crystal Elastomers (rather than complex engineering of interacting mechanical parts), namely the coupling of two different degrees of local freedom: the translational (responsible for strength and elasticity) and the orientational (arising from liquid crystalline order, and responsible for the equilibrium shape).

Liquid Crystal Elastomer actuation

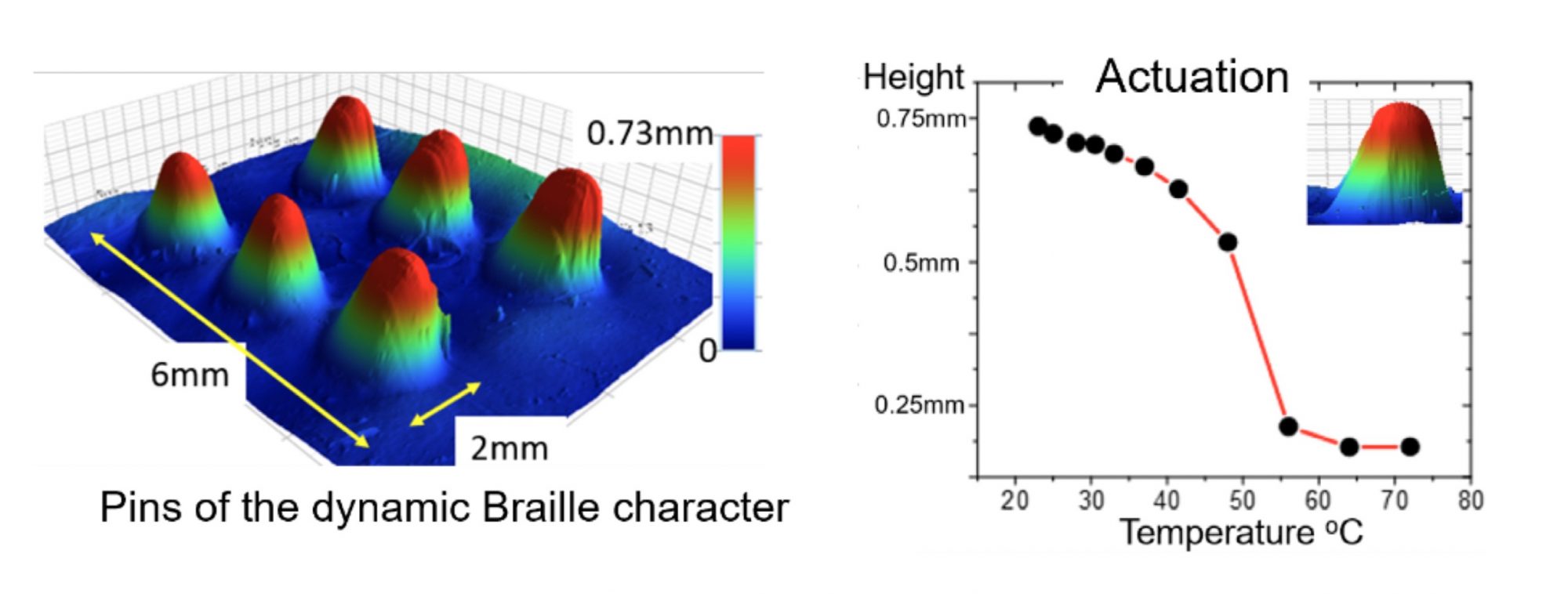

Altering the degree of local order, by heating or by other stimuli, results in the matching change of natural shape of the material – which could then be designed to exert a force or produce mechanical work. The remarkable characteristics of LCE actuation (fully reversible action; large amplitude, with a stroke of 5%-300%; stress-strain-speed response almost exactly matching the human muscle) make it highly attractive in biomedical engineering, soft robotics, smart textiles, and other fields.

Yet, there is a profound difficulty (a bottleneck), which remains the reason why this concept has not found its way into any practical devices and applications in all these years. LCE actuation requires alignment of the local anisotropy (monodomain structure) in the permanently crosslinked polymer network – which has been impossible to achieve in any useful large-scale configuration except the thin flat film, due to the unavoidable restrictions of two competing processes: orientational alignment and network crosslinking. Several spectacular demonstrations of actuation by bending the thin film have been put forward, including self- propelled robots, yet one cannot expect to obtain any significant mechanical force or extract work out of such bending motion.

Understanding LCE vitrimers

Recently, we made a breakthrough, developing LCE vitrimers (polymer networks covalently crosslinked by a bond-exchange reaction). Vitrimers are much more stable than other transient elastomer networks, but still allow thermal re-moulding (making the material fully renewable). This makes it possible to create complex shapes with intricate local alignment (which are impossible in traditional permanently elastomers).

The University of Cambridge, through its ERC-funded APRA project, and the technology spinoff Cambridge Smart Plastics are now jointly developing this new elastomer concept, bridging across from the academic research to marketable technology. We are tuning the material design for robust Liquid Crystal Elastomer vitrimers, imparting photo-actuation capacity with a controlled wavelength, and finally utilising them in practical-engineering actuator applications where the reversible mechanical action is stimulated by light, solvent exposure, or more traditionally – heat/cool cycles.

These applications include (but not limited to): continuously spinning motor to convert ‘waste heat’ into mechanical work, dynamic Braille display changing the tactile characters on demand, capillary pump and toggle flow switch for microfuidics, and active textiles woven from Liquid Crystal Elastomer fibres and yarn that reversible change their 3D shape on heating and cooling. All of these directions offer radically new ideas to industrial product designers, which are only now beginning to realise the opportunities brought about by liquid crystalline elastomers.

More About Stakeholder

-

Researching polymer physics at Cambridge University

Professor Eugene Terentjev discusses researching polymer physics in the Cavendish Laboratory at the University of Cambridge.

Access Rights | Content Availability:

Access Rights | Content Availability:

APU Content Aggregation Service

APU Content Aggregation Service